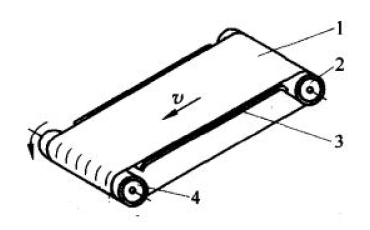

Although there are some differences in the form, the structure principle is the same. Belt conveyor structure principle as shown in figure -1.

Schematic diagram of -1 belt conveyor structure principle

1- conveyor belt; driven wheel 2-; 3- plate or roller; 4- driving wheel

As shown in figure -1, the most basic belt conveyor line consists of the following parts, the functions of each part respectively:

The conveyor belt (1)

Workpiece conveying or material. The conveyor belt running, the friction between the workpiece and the material or rely on belt moves together with the workpiece conveying belt, or from one location to another. The top of the belt need to transport the workpiece, bearing; below the belt does not work for the return period.

(2) driving wheel

Direct drive belt, and the friction between the belt on the belt running wheel drive.

(3) from the wheel.

The supporting belt, the belt of continuous operation.

(4) or plate roller

Directly supporting the belt and belt above the workpiece or material, not to make the belt sag. To keep high smoothness requirements when the occasion is usually below the belt running in the belt conveying section of the supporting plate with a plate, or simply by the roller can rotate freely. Because the belt return section does not carry the work piece, usually uses the supporting roller bearing.

In addition, the system also includes a belt conveyor:

(5) positioning baffle

Because the workpiece conveying generally need to make the work to maintain a certain position, so usually on both sides of the design positioning baffle conveying belt or gear, the workpiece is always in the linear movement direction.

(6) the tensioning mechanism

Because the belt will produce relaxation in the movement, so it is necessary to have the tensioning mechanism of belt tensioning mechanism were investigated, the essential is the belt installation and removal mechanism.

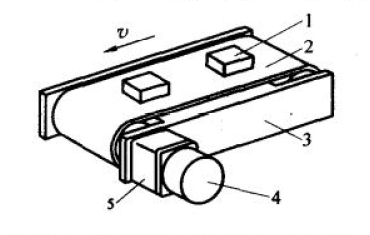

(7) motor drive system

The driving wheel movement must be driven by the motor drive system, usually by the motor through the speed reducer through the gear drive, chain drive or synchronous belt drive belt driving wheel. There will be a motor through reducer belt driving wheel is connected directly with the lower part, save space. As shown in figure -2.

Figure -2 motor and reducer is directly connected with the driving wheel belt conveying system

1- 2- 3- belt; workpiece; baffle; 4- motor; 5- reducer

Usually a motor system capable of driving load limited, for a longer length (e.g. tens of meters) of the belt conveyor line, usually by several independent belt conveyor system installed in a straight line with splicing, there will be several independent of the belt conveyor system according to the same height fix in a transmission line.

The belt conveyor is driven by friction between the workpiece and the belt of conveyor belt conveyor, so the power is generally small, the transportation of materials including workpiece and bulk single material, mainly used in manual assembly line, electronic communications, electrical appliances, light industry, food industry, especially the electronics manufacturing industry in China the Pearl River Delta, Yangtze River Delta region using belt conveyor line composed of manual assembly lines, so the workpiece conveying is a small, lightweight single product. There are a few belt conveyor used in special occasions such as large load, mining, construction, food, docks, power plants, metallurgy industry, automation for bulk material transportation.

Figure -3 is used for the large belt manual assembly line conveyor line for example, figure -4 is used for small belt material conveying line example.

Figure 3- belt assembly line

Figure -4 small belt conveyor line

In the case of the small belt conveyor line shown in figure -4, the transmission line can be adjusted to a certain direction according to the actual need to be adjusted to a certain direction in the direction of the horizontal direction.