|

|

|

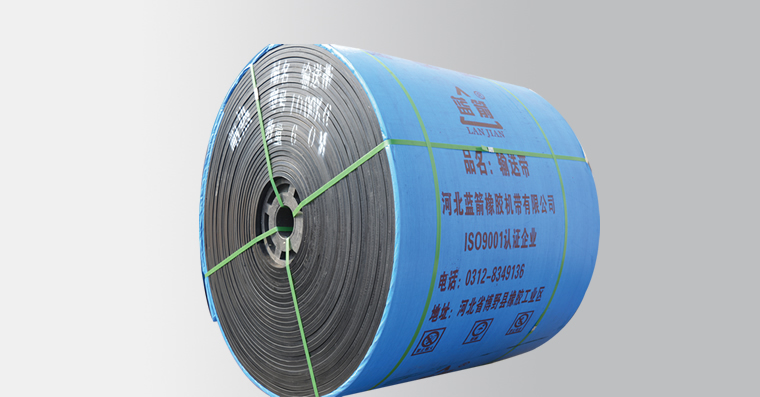

The tensile body of polyester cotton conveyor belt is interwoven by cotton-polyester blended fabric in longitude and cotton fiber in latitude. The belt body is thinner and lighter, better shock resistance, so the belt has greater functional performance, of energy conservation and consumption reduction, and gain more benefits.

Application fields: Metallurgy, steel plant, building material and construction, energy, chemical,machinery equipment and port.

Tensile Strength: 200-800N/m Width: 500-2400mm |

|

|

|

|

The belt carcass of this product is EP fabric(D.S.EP or CC56) of high modulus,low shrink,and high breaking tensile strength.Cover rubber of this product uses SBR, CR, EPDM rubber or Chloroprene rubber that has very good high temperature resistance.The belt is made with extra care after mixing rubber with high temperature resistant materials, assembling and vulcanizing.

The carcass of this product has very high adhesion after the special treatment of coating and shaping.Under normal working temperature of below 180℃, the belt is low in elongation, excellent in anti-abrasion,and can bear 250℃(in the cooling condition, 300℃-600℃) high temperature for a short time.The belt is suitable for use in cement,metallurgical and steel industry. |

|

|

|

|

Nylon is one of the best quality synthetic fibers that rubber industry use nowadays. The nylon canvas is woven by nylon fibers both in warp and in weft, it is the most widely used fabric in rubber industry, and its outstanding merits are high abrasion resistance, high tensile strength and good fatigue resistance. Conveyor belts with nylon canvas inside have the characteristics of thin belt body, high tensile strength,good shock resistance,good trough ability,high adhesion between plies, splendid flexibility and long working life. Nylon conveyor belts are suitable for medium, long-distance and heavy-load transportation of materials.

Description:

Feature: Basic strength material is NN fabric. (Both the warp and weft are NN66). Applied in the situation that long distance, heavy impact and heavy abrasion.

Application Fields: Metallurgy, steel plant, building material and construction, energy, chemical, machinery equipment and port.

Tensile Strength:80-3000 N/mm Width: 500-3200 mm |

|

|

|

|

|

Polyester conveyor belts,also called EP conveyor belts,whose tension resistant body is canvas woven by polyester in warp and nylon-66 in weft.The belts have the characteristics of low elongation in warp and good trough ability in weft,good water resistance,good wet strength,no mould, suitable for medium,long-distance and heavy-load transportation of materials.Because of the high initial modulus of polyester,the belts can choose a relative low safety factor

Application fields: Metallurgy, steel plant, building material and construction, energy, chemical,machinery equipment and port.

Tensile strength:80-3000 N/mm Width:500-2400 mm

Features & Benefits:

1、Reduced strength

The combination of fabric design and dip process provide less elastic and permanent elongation on all specifications. This minimizes take-up concerns and reduce the number of splice at break-in.

2、High-modules, superior troughability characteristics

With the high-tension PET warp and NN66 fiber could provide the belt high-modules and superior troughability characteristics.

3、Variety choices of cover types and thickness |

|

|

|

|

Both top and bottom covers are PVC, thickness of each side can be up to 4mm, the belt has much more advantages than non pressed PVC belt on impact resistance, water, with longer service life, higher fastener holding.

Application fields: Metallurgy, power stations, chemical and metallurgy industries.

Tensile strength: 500 ~ 2500 N/mm. Width: 500 ~ 2000 mm. |

|

|

|

|

|

Both top and bottom covers are PVG compound, much suitable to working at higher slope(better no more than 20 degree).

Application: Metallurgy, power stations, chemical and metallurgy industries.

Tensile strength:500~4000N/mm Width:500~2000mm.

Features and Advantages:

1.Advanced soakage technology

The unique solid woven belt soakage technology can make PVG paste soak well. Thus, the paste and solid woven fabric become the all and the one, which ensures the belts impact resistance property.

2.Cover rubber with excellent properties

The special cover rubber of PVG solid woven belt has excellent properties, which represent at excellent physical properties on the basis of ensuring the safety properties. Thus, the cover rubber can give the carcass first-rank protection.

3.Bone materials with high tensile strength

The special multiple tiers integrate with each other so as to reach high tensile strength and weft&warp tear resistance, light carcass weight, and save the power energy for transportation.

4.Excellent flame resistance property |

|

|

|

|

Corrugated sidewall conveyor belt generally is used with corrugated wall conveyor together, and also used with general belt conveyor. It is suitable for the horizontal, short distance condition..The angle will be not less than 30 degrees.

Characteristics:

1.Materials can be conveyed at a large slope up to 90 degrees.

2.The belt has large loading capacity and the materials cannot be scattered.

3.The slope of conveying can be changed from horizontal to sloping,or from sloping to horizontal.

4.The conveyor is simple in structure,flexible in arrangement and occupying only a small area. |

|

|

|

|